LASER SCANNING ADDED TO DIGITAL TOOLBOX

By Ryan Barker, CM-BIM, Virtual Design Manager

We have come a long way from the days when data collection on a Jobsite only meant grabbing your trusty tape measure and field book to record dimensions. While the tape, auto level, theodolite, and robotic total stations all remain essential tools for layout and data collection, laser scanning gives us a new level of precision and speed when it comes to recording the physical world. Wayne Brothers Virtual Design & Construction (VDC) group is proud to now offer Laser Scanning service.

How it works

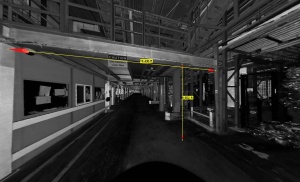

Like the way a total station uses electronic distance measuring (EDM) to measure the distance from a prism, a laser scanner uses a laser beam to measure the distance from everything around it. Rather than collecting a single point at a time, the scanner collects around a million points a second! The points from multiple setups are combined (or registered) to create a point cloud that can be imported into various applications.

The scanning process only takes a few minutes per setup, and the results of each scan are immediately visible on the Trimble tablet. These are the same tablets used by our VDC team for robotic layout, so the scans can be compared to our project models in near real time.

How we are using it

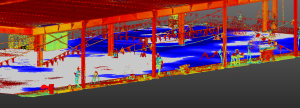

The scanner has been used on many projects to collect existing and as-built conditions. At one of our Frito-Lay projects, we have scanned several areas for use in Southern Engineering Company’s (SEC) design efforts. Bringing the point clouds into Tekla allows us to design around the myriad of pipes and other structures inside the plant. Automated clash detection helps confirm that our new structures will fit without issue.

Another common use for the scanner has been collecting as-built data. At the Charlotte Airport project, laser scans are being used to produce .pdf heat maps that show floor flatness. Pre and post-pour checks are performed to ensure wall plumbness, embed and anchor bolt locations, and general conformity with design.

Our new laser scanning capability enables quick, precise, safe, and thorough data collection. All with minimal interruption to the client and/or jobsite operations. There are many more uses for this technology, and the VDC group looks forward to continuing its implementation across all parts of Wayne Brothers’ operations. If you have any questions or would like to set up a scan, let us know.