Process Piping Contractor

Tight schedules. High-security settings. Stringent project specifications. We have the experience to handle it all. Wayne Brothers is the industrial piping contractor of choice for plant reconfigurations, upgrades, and expansions.

The Wayne Brothers Difference

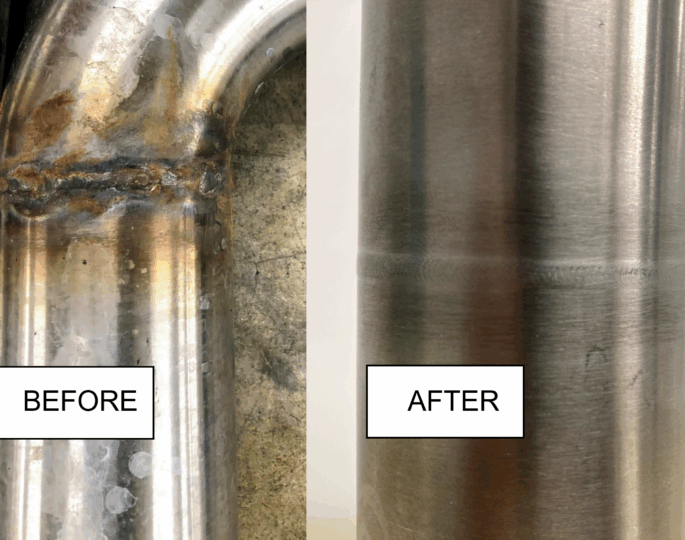

Experienced Field Welders + Fitters

We cross-train and develop our welders and fitters in-house. This empowers us to keep our people safe, all while staying flexible and adapting to client needs.

Shop Fabrication Capabilities

We can design and fabricate piping systems before installing them on site. Off-site prefabrication leads to improved quality and schedule.

Vertically Integrated Supply Chain

We source material from our sister company, Preferred Supply, resulting in lower costs and insulation from some supply chain issues.

Industrial Process Piping

Wayne Brothers excels in industrial piping solutions. Our welders are certified in TIG and orbital welding, and our team can design and install process piping for projects large and small. We have extensive experience in high-purity applications, glycol, wastewater treatment systems, industrial gases, and dry ingredients using 3A standards and a clean design methodology.

Industrial Utility Piping

We also handle all on-site utility piping to support your operations. Our crews fabricate and connect pipes for compressed air, steam and condensate, chilled and hot water, and tower water. We can also accommodate whole-plant utility systems.

Process, Utility, + Packaging Equipment Installation

The Wayne Brothers team has the expertise to install equipment unique to the food and beverage industry, including specialized process, utility, and packaging systems.

Pipe Dreams Made Real

We specialize in complex process and utility piping. Contact us about your project.