3D Construction Modeling

VDC isn’t a service we tack on in addition to our typical scopes — it’s the cornerstone of our approach. Our models guide everyone on the Wayne Brothers team, from the office to the field.

The Wayne Brothers Difference

Planning, Estimation, and Budgeting

We’re known for extremely precise plans, estimates, and budgets. All are made possible through refined renderings.

Real-Time Drone Captures

Take your inspections to the next level with drone data. Our drones monitor project progress, updating our models in real time.

Project-Changing Models

Our BIM modelers analyze plans and specs, detecting and resolving clashes. We’re proactive and come to you with solutions.

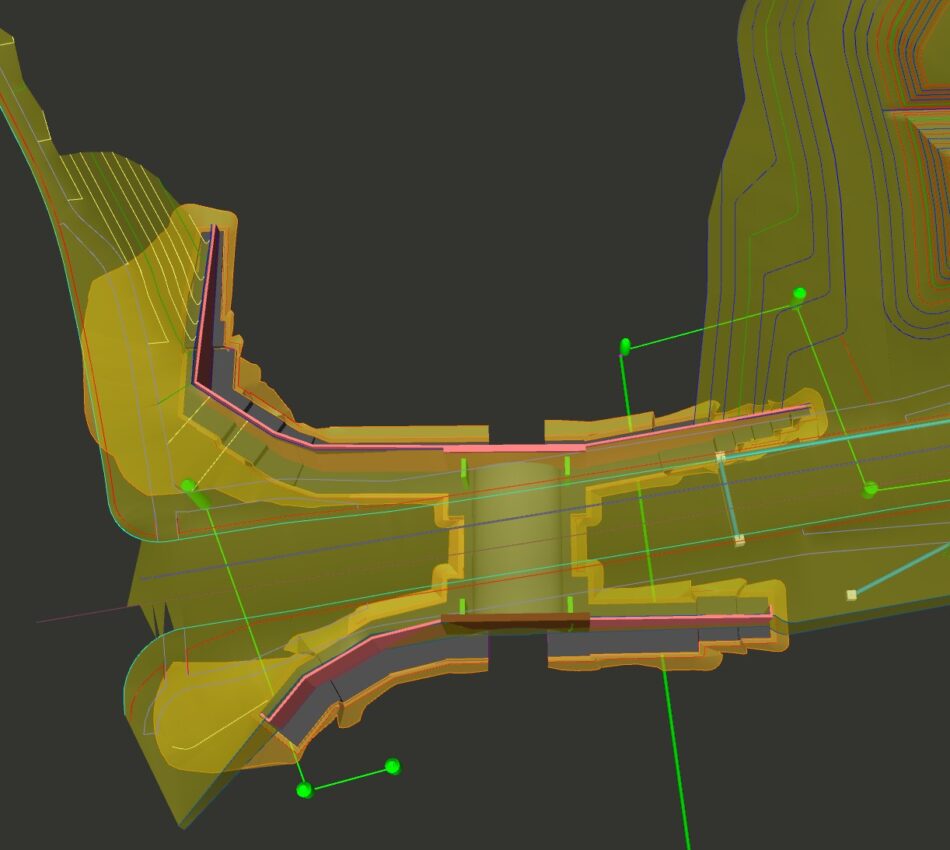

Your Project, Rendered in Full Detail

We demystify underground work with robust models. Our field-verified models are construction-ready, empowering our team to identify and prevent clashes in project plans. Wayne Brothers builds every model to a construction-grade layout.

Building Information Modeling (BIM)

Get an up-close look at every phase of your build. Wayne Brothers models all the elements that matter to your team, providing BIM services tailored to your workflow and project specifications.

In-Field Communication

VDC powers our on- and off-site coordination. We update models in real time, sending the most up-to-date information to our crews in the field. Everyone works from a single source of truth.

Modeling To Ensure Constructability

We deliver clash-free construction. When pre-fabrication is practical, Wayne Brothers fabricates from the same model we use on site, meticulously matching the design as we intend to build it.

Build Virtually Before We Ever Break Ground

Stop leaving your projects up to chance. Wayne Brothers’ VDC capabilities offer proactive solutions to ensure your success.